Business Hours: Tuesday - Saturday 9 a.m. - 5 p.m. (PST)

For a Square e-Gift card holder, please contact us before placing an order with it. Thank you!

Our Toolmakers

Our carefully selected toolmakers, while hailing from various parts of Japan, all have one thing in common: their dedication to craftsmanship and quality. These are some of their stories...

Yamamoto Planes: A Father-to-Son Tradition

The Yamamoto plane crafting story began in Miki-Shi, on the island of Honshu, in 1903. There, a young man named Kiichi Yamamoto entered into an apprenticeship with the well-known master blacksmith Utaro Kurokawa. Over the next 16 intensive years the student himself became a master, and in 1919 the Yamamoto Plane Company was born.

Kiichi's reputation as a maker of fine steel tools had been well established when, in 1945, he took on as an apprentice his own son Katsuzo (later to become master blacksmith Katsusaburo). This father-to-son tradition continues today with Yoshihiro Yamamoto (or, third generation master blacksmith Tetsushinsai Horaku, as he became in 2010 when he passed the prestigious “Miki Dentoukogeishi” test) and his son Kensuke. Together, they carry on the Yamamoto legacy by respectfully adding their considerable experience upon centuries of accumulated blacksmithing science.

Inomoto Plane Blocks: No Compromise for Quality

Founded in 1578, the small town Yoita-cho, on the island of Honshu, was primarily home to blacksmiths who specialized in making swords for the Samurai elite. At the end of the Samurai period, however, the talent of the blacksmiths was redirected and the families of Yoita-cho branched out to produce high quality hand forged tools for temple builders throughout Japan. Today, the unbroken legacy of excellence continues to be passed down through the generations, with products from this small town being highly treasured by woodworkers and craftsmen around the globe.

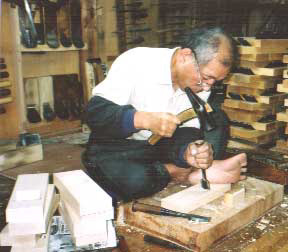

It was in Yoita-cho over 50 years ago that Mr. Inomoto took over his father's small workshop and, using the same traditional tools and ancient machinery, began creating his plane blocks and perfecting the skills he would need to achieve the worldwide recognition he enjoys today.

|

|

Mr. Inomoto and the oak wood he carefully selects actually live under the same roof. The upper part of his home houses two floors of four foot high stacks of precut wood blocks separated by small pieces of oak to allow for the natural slow drying of the future plane bodies. It takes at least four years to get the desired moisture content, and under no circumstances will Mr. Inomoto shorten this process. For ten or more hours a day he sits on the floor, expertly working the plane bodies to a perfect finish.